Subsoil water causes difficulties for deep excavations during foundation construction. This obstacle is a challenge for engineers, which they can overcome through a dewatering system like the wellpoint. This system acts as a tool for reducing water below excavation levels.

The system of wellpoint dewatering comprises shallow well chains called well point. The wellpoints are set up at pre-decided depths. And adequate distance apart.

This dewatering system is a convenient and versatile method for dewatering silty sand low flows and coarser gravel high flows. Shallow trenches also need around 50 to 70 well points.

The Definition of Wellpoint System

Typically, a wellpoint system is an ordered series of shallow wells with compact diameters. These wells are connected to a pump. The installation is done through rotary drills or, sometimes, water jetting. Vacuum technology is used to pump water in a high-efficiency dewatering pump connected to the system through a header main pipe.

This system is usually used when the working conditions of the excavation sites need to be stable through lowering of groundwater level. Shallow foundations and trench works are the main areas where the dewatering system is suitable.

Wellpoint System Explained

Through this technique, engineers initiate dewatering throughout the land allotted for construction. This way, the project area gets protected from shoring. Following the procedure, a discharge line is set up in the area using pump set connection series.

The Mechanism of Wellpoint Dewatering System

The wellpoint system mechanism is quite simple to understand. There is fundamentally a pipe having an opening. This opening is mechanized such that not only does it allow water to enter but also keeps away the movement of water-bearing formations. Generally, the opening of a wellpoint pipe is around 38 to 50 mm in diameter.

Parts of a Dewatering Wellpoint System

The parts that make up a dewatering wellpoint system are as follows :

- A dewatering pump for water extraction

- A riser pipe connecting the wellpoint system to the surface

- A shallow shaft

- A small well for filling extracted water

It is important to know that there are various openings of the riser pipe in the bottom area to allow water to be extracted towards the surface. The openings have sizes that are based upon the formation material grain size.

Varieties of Dewatering Wellpoint System

The dewatering wellpoint system comes in many varieties and designs. The most popular among them is the PVC well point system. This PVC system is generally used in areas where irrigation systems are found. Also, locations with artificial and natural ponds usually install the PVC dewatering wellpoint system.

An alternate system of dewatering wellpoints is the borehole system, which is rather costly and time-consuming comparatively. It makes the wellpoint system more cost-effective and quick. However, it is ideal for areas where shallow depth is desired. The wellpoint system cannot retrieve large water qualities. Ordinarily, the wellpoint system extracts five gallons per minute of water with 5 m to 6 m in height. If greater water depths need to be extracted, the engineers install another lot of wellpoint systems at a lower level.

Why is dewatering necessary during excavation?

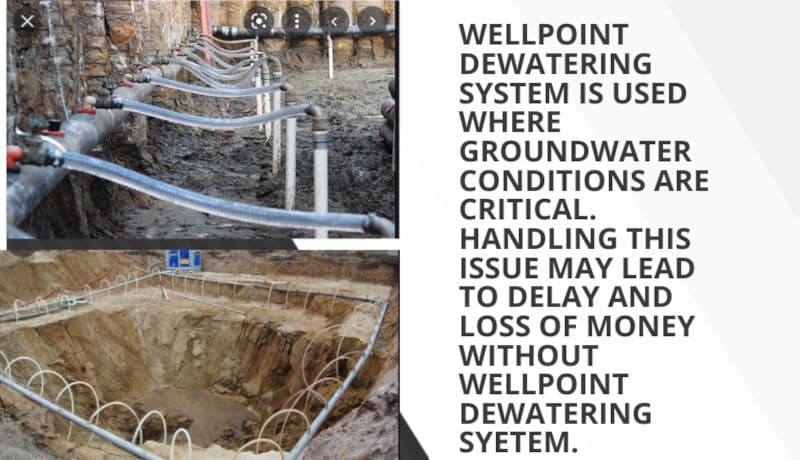

Groundwater conditions become critical in many underground excavations. If groundwater is not handled adequately, huge money loss and time delay will be experienced. This is why the dewatering system is deployed during excavation operations. One of the most effective dewatering systems is the dewatering wellpoint system.

The requirements of the excavation site are kept in view while placing pumps at a sufficient distance. To draw groundwater with a wellpoint system, it should be ensured that the water stratum is permeable. If this requirement is not met, water cannot be drawn from an excavation site through the dewatering wellpoint system.

Types of Dewatering Wellpoint Systems

There are different dewatering wellpoint system types. These include the single-stage wellpoint systems and the multi-stage wellpoint systems. Details regarding both are given below :

Single-Stage Wellpoint Systems :

The single-stage wellpoint system comprises a pipe length of 1 m and a diameter of 50 mm. A screen covers the apertures so that prevention of clogging can be ensured. A jetting nozzle is also provisioned at the lower end, which acts as a wellpoint called the derive point.

The lower end of the single-stage wellpoint system also includes a ball valve designed to prevent water flow in the opposite direction. Another pipe, called the riser pipe, has the same diameter as the wellpoint and is linked to ground level from the bottom end.

The riser pipe connects the header pipe, also called the horizontal pipe, further linked to the pumping unit. While the dewatering wellpoint system is installed, water pours downwards at the predetermined depth. Till the process of excavation is complete, the system can be used, provided the excavation depth is below 4.5 m. They are also more effective when the soil is granular.

Multi-Stage Wellpoint Systems :

A multi-stage dewatering wellpoint is required when the water level depth at excavation sites exceeds 4.5 m. Moreover, if the area is a slope, it is recommended that the multi-stage wellpoint system be set up in stages.

First-stage of Multistage Wellpoint System :

Multi-stage well points are instituted at 4.5 m depth. This positioning becomes the first stage. In this stage, the water level decreases.

Second-stage of Multistage Wellpoint System :

In the second stage, the area that surrounds the wellpoint is excavated. Also, a second wellpoint is set up, which reaches a further depth of 4.5 m. This process is repeated till all water is excavated. However, there is a limit to the excavation depth, and it does not remain effective after 15 m.

Dewatering Wellpoint Installation System

High pressure jetting pumps are used for the installation of dewatering wellpoint systems. Tubes are placed using self-jetting well points. The most commonly used jetting pumps have a 20 L per second water supply rate. Water is supplied with the jetting hose. Jetting hoses use standard fire hoses having male and female connectors.

The jetting process becomes an arduous task in case the strata contains gravel. High power jetting pumps are used for heavy-duty uses, for instance, pile jetting. Also, a constant supply of clean water is essential for the process.

After the first installation, if the need develops for installing more wellpoints, they can easily be done quickly. These additions make the system flexible. This addition also comes in handy when the excavation period is short.

Dewatering Wellpoint System Application

Commonly, the application of the wellpoint system is temporary. Following are its applications :

- The engineers and contractors use it to lower groundwater levels.

- Also, it is applied for the establishment of drainage systems for excavations.

- Another application is to lower groundwater to construct subways and stabilize land to avoid catastrophes.

- Through dewatering, water can be obtained for irrigation, household purposes, etc.

- When there is a need to lay a deep sewerage line, a dewatering wellpoint is used.

- For tunnel excavations, hydro projects, including canals, underground water tanks, etc.

- For the construction of bridges.

Advantages of Wellpoint System

Easy to Maintain

The Wellpoint system is an uncomplicated procedure, which is easy to maintain. The ease in maintenance is due to a lack of sophisticated or complex tools.

Quick Deployment

Unlike other complicated dewatering systems, the wellpoint system deploys quickly. This makes the project take less time and speeds things up. Also, most ground conditions are compatible to use a dewatering wellpoint system.

Versatility

Wellpoint dewatering systems can be used for both small scale and large scale projects. The equipment holds good in both cases. Even if there is very limited space available, self-jetting well points can be used to fulfil your dewatering requirements.

Affordability

The dewatering wellpoint system is cost-effective and affordable, especially compared to other dewatering procedures.

Compatible with many Soil Types

The dewatering wellpoint system is compatible with many kinds of soil and works best on most. Even the stratified soils can be dewatered through a wellpoint system.

A More Productive Method than Deep Dewatering System

The Wellpoint system is more effective and productive than the deep dewatering method. This effectiveness is due to the coverage of large areas in the wellpoint system. Also, the dewatering wellpoint system can work consistently at a water capacity of 100 m per hour.

Disadvantages of Dewatering Wellpoint System

The dewatering system does not remain as effective in the fine-grained soil as with sand and gravel. There is a limitation for the suction lift to 3.5 m to 4.5 m in fine-grained soil, whereas in sand and gravel, the suction lift increases from 5 m to 6 m. In addition, due to access restrictions at sites, you might face problems using header main.