Dewatering is the procedure of extracting surface or groundwater from a particular location. In areas with significant water ponding, construction work cannot occur, so techniques have been developed for moving water out of each area before construction begins.

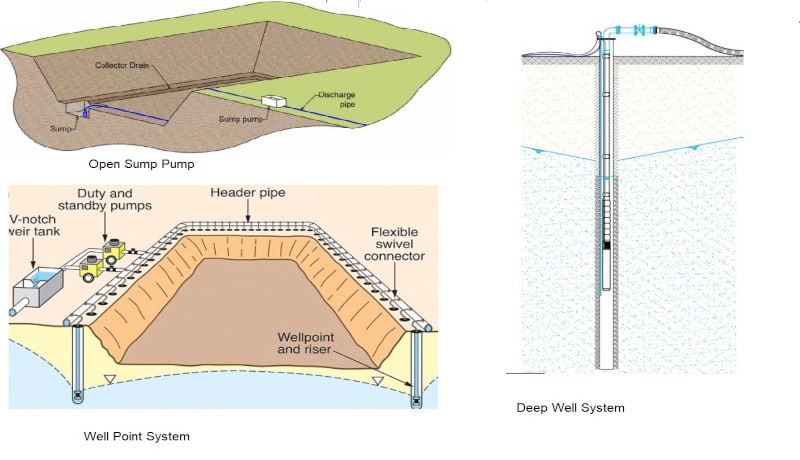

The process typically involves sloping the work areas to drain water away and, pumping surface water to another location. It also means drilling a series of well-points into the ground around the area of work and pumping it to another location to lower the water table while work is occurring.

Advantages of Dewatering Your Construction Area

The most common use of dewatering techniques is made in the construction industry. Dewatering is a crucial process on almost every construction site. Dewatering a construction site has multiple advantages. These include:

1. Stable Soil and Work Area

When excess water is dewatered in a safe manner, it reduces the risk of unstable foundations, mudslides, and equipment failure caused by bogging. In addition, this ensures that your worksite is ready for digging, preparing the foundation, and footing cement.

2. Employee Safety

Dewatering an area can help keep your workers safe and healthy. Standing water usually becomes polluted and poses many health risks for crews, managers, their families, and communities surrounding the construction site. In addition, it heightens the risks of workers getting injured on the job due to accidental slips and falls.

3. Scheduling

The construction site can encounter obstacles at any phase of construction, including flooding caused by incessant downpours and unforeseen storms. Successful dewatering can prevent unnecessary delays.

4. Preserve Costly Equipment

Excess moisture from standing water can impact your construction equipment and building material. Using dewatering measures to eliminate excess water on your worksite and equipment storage areas can prevent project delays and budget overruns.

5. Environmentally Friendly Surrounding

Over time, standing water can cause erosion. It can also collect debris and toxins from airborne pollutants. Proper dewatering techniques eliminate polluted water and its harmful contents, preventing risks, and making the work site more environmentally safe.

Where Can Dewatering be Used?

Dewatering is used in many industries to minimize waste and convert liquid waste into solid waste for disposal. In both small and large projects, dewatering can result in substantial cost savings.

Dewatering is utilized in many industrial and non-industrial processes. These include:

1. Manufacturing Companies:

Manufacturing companies use dewatering procedures to create more productive internal wastewater elimination systems. Disposing of any natural or artificial material will require quite a lot of space. This can get pricey for a company, considering the cost of maintenance and storage. The manufacturing job can run more efficiently if dewatering is done correctly, reducing ground pressure.

The dewatering techniques allow companies to expedite the process of drying and hauling sludge. This culminates in substantial stress being released away from manufacturing companies.

2. Construction Companies:

Many dewatering pumps are employed in important stages of the construction process. These dewatering pumps aid in extracting the groundwater at a construction site before a building’s foundation is finalized or placed.

To ensure a safe and secure workplace and environment, it is vital to draw water from excavations, trenches, and places with sketchy slopes. Builders typically use submersible pumps, wellpoint systems, trash pumps, and other products to drain the assigned area swiftly and efficiently.

3. Flood Management

Flood management is essential to improve and maintain quality of life during a calamity. Standing water and heavy water movement can result in long-term problems if not resolved with dewatering pumps.

It does not matter that the flood resulted due to extreme rainfall, high tide, hurricane, tsunami, or a succession of dangerous weather events. Dewatering can help towns salvage dry ground before or after an emergency. Florida is no stranger to these natural phenomena. Florida Dewatering can be addressed by consulting companies that provide rentals and reliable services for all your flood control needs.

High volume dewatering pumps have extra space as part of a permeant network of dams, levees, and other barriers employed to obstruct further water flow in case of a flood. Moreover, they can offer the needed short-term pumping capacity of floodwater when paired with other temporary water maintenance attachments such as aquafences, bunds, or sandbags.

4. Water Transfer

Water transfer involves diverting water from canals, rivers, oceans, and other inlets of water to areas where water levels are low. Water transfer equipment can help saturate low water environments as well as repair damaged water pumping systems. It can provide solutions in many areas of industrial applications. The advantage of using dewatering pumps is to bring water to an area that needs it immediately. Dewatering transfer pumps can facilitate an increased flow of water. The excess water extracted from construction sites can be used for irrigation as well as to encourage a healthy, blooming environment.

5. Sewer & Wastewater Pumping

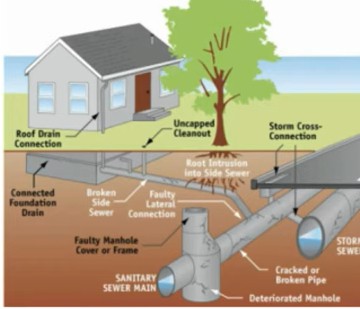

Dewatering is the solution that helps operate a sewage treatment system. Dewatering pumps can be bought or rented for municipalities, construction projects, and industrial applications.

Flooding of the sewers often requires dewatering pumps. Besides being used for leak detection, they can also be used to clear clogged pipes. Dewatering ensures that the sewage and wastewater do not contaminate freshwater sources. Failure to dewater sewage can cause residents to get sick, and freshwater can be infected with bacteria and other materials.

Most industrial wastewater comes from power plants that burn fossil fuel, especially coal-fuelled plants. The wastewater discharged by these plants contains significant levels of metals such as cadmium, lead, chromium, and mercury as well as selenium, arsenic, and nitrogen compounds.

Water-treatment processes, whether municipal or private, include dewatering to reduce the amount of sludge. Sludge is produced when wastewater is treated before being released back into nature. Wastewater treatment liquid sludge contributes significantly to disposal costs. The more efficient your dewatering process is, the more you can reuse water while reducing your plant’s maintenance and operating costs.

6. Water Infrastructure Security

The concept of water infrastructure security refers to the process of guarding or preserving water systems including canals, rivers, lakes, drinking water, aquifers, tanks, or water towers, from pollution or sabotage.

Dewatering large-volume pumps can aid with water infrastructure security. Infrastructure security also manages the conservation of prime structures, such as highways, power plants, financial services, security services, and transportation facilities in a city, community, or society.

Dewatering companies can support by providing emergency pumps, backup systems, pumping water from other sources, and restoring impaired pumping equipment.

7. Mining Operations:

Dewatering is a crucial process for ensuring efficiency and effectiveness when mining. Flooding can occur in most mine operations, but some are more susceptible than others. The groundwater will infiltrate when a mine is below the water table. Heavy rainfall, high water tables, nearby rivers and lakes can cause catastrophic flooding, causing costly shutdowns.

Bringing down hauling costs is another reason dewatering is important in the mining industry. For the most part, the final product is water-free, or water has been significantly removed to make transportation easier and cheaper.

The dewatering process can involve removing standing water from low points in the mine. Due to groundwater, runoff, and seepage from nearby bodies of water, a mine can encounter several difficulties that will hamper its operations. Dewatering is also used to feed equipment for optimum operation.

Modern dewatering is more advanced and effective, using different types of pumps to remove water and transport it to a containment area. Dewatering is possible even in underground mines thousands of feet below the surface.

Conclusion

Ground water level is usually considered hazardous to construction and mining sites. But, that’s not completely true. It can be hazardous to many other industries like agriculture, flood management, and sewage. Therefore, the use of dewatering techniques is inevitable in many other areas including construction and mining sites.